How do you build your best broom? [via YouTube]

Check out some of these free videos created by broom makers!

CLICK HERE FOR COBWEB INSTRUCTION PAGE WITH PICTURES.

Click here for a whisk instructions and other short course.

Build your best broom.

CLICK HERE FOR COBWEB INSTRUCTION PAGE WITH PICTURES.

Click here for a whisk instructions and other short course.

You want to start making your own brooms? You came to the right place. Whether it is going to be a large scale operation, a weekend hobby, craft fairs, or something else, Caddy Supply has got you covered.

For most new broom makers, we recommend the following items:

10 lb. box of craft broomcorn - Craft is the broomcorn needed for any type of braiding or weaving of the stalks. Perfect for round brooms or cobweb brooms.

Twine (Nylon or Hemp) - The $15 tarred black twine is the highest strength and will help grip to the broomcorn

Optional for sewing - Needle, Stitching clamp, knife

Optional - Handles, 12” ash is perfect for cobwebs, we also have 48” handles for kitchen brooms.

If you want to build different types of broom with processed hurl, we recommend the following lengths.

Standard Kitchen Broom- 18" +

Turkey Wing Whisk - 14, 16, or 18"

Mini Whisk Broom- 14"

Pot scrubbers - 12"

Depending on what type of broom, we realize you also might need knives, processed hurl, scissors, a tying table, a footwinder or a tying frame. You will also need some way to soak the broomcorn before starting the broom making process. For a standard kitchen broom, it takes about 13 oz to 16 oz. of hurl. You will have to plunge the broomcorn in a sink for 5 to 10 seconds, then promptly remove it and let it dry for about 10 minutes. Once the broomcorn is more suitable to work with, you can start winding around a handle.

We also have information regarding broom equipment including kickwinders, sewing vices, and broom trimmers.

Further reading material and instructions on whisk making, please visit here!

Overall, the team at Caddy expects the 2017 crop to be slightly smaller or same as 2016 crop due to ongoing sugarcane aphid issues. However, we have inventory to supply all size crafters and not anticipating any stock-outs.

The 2015 crop was almost completely destroyed by yellow sugarcane aphids, also called sorghum aphids. Mexican farmers lost about 90% of everything planted. In 2016, farmers began to fumigate the broomcorn and fields that were fumigated every 2 weeks were successful. Unfortunately, treatment is expensive and not all the farmers have the money to fumigate.

In more hopeful news, farmers planted some of Dr. Sam Moyer’s seed in 2016 and with fumigation it produced nice-looking broomcorn, now in our warehouses (pictured: Dr. Sam Moyer with some craft broomcorn grown from his seed). Our staff is working with Dr. Moyer to try to develop an aphid resistant broomcorn.

Every year has 3 main harvests. The winter crop grown in southern Mexico is harvested in March, received at our warehouse in April-May. The spring crop is harvested in June-July from western and northern Mexico, available typically around August. The fall crop grown in northern Mexico is harvested in October, available in the November and December time frame.

Like so many things in life, there is much more to a 'simple' broom upon second glance.

We talked about what broomcorn is exactly and what it is not in our first installment, now its time uncover why is broomcorn the best for sweeping and different types of corn brooms.

Below, Luke Lewis of North Woven Broom describes the first used broom, the round brush broom made with craft broomcorn to now most commonly used flat Shaker style broom.

Start at 0:22 seconds into the YouTube video below to see a simple way the broomcorn is cleaned. Karl is using craft broomcorn (we sell ours already cleaned!) with the stalks attached but does not weave them.

In the simplest way, you can make a broom by hand by using wood pegs, a handle, twine, broomcorn, and tools. He makes a first layer using 8 stalks, wrapping, and pulling the twine around the handle. He covers it with a second layer, using around 16 stalks total.

For a detailed instructions on broommaking, please visit here.

Did you know that there is still a broomcorn festival every year in Arcola, IL ?

Check out details here !

How many times have you tried explaining to people what you do for a living?

'I craft brooms.'

' How?'

'Well first you need some high quality broomcorn...'

On our side, we like to say we are broomcorn dealers. A business that started back in the 1900s by my grandfather who shipped broomcorn across the US by train or delivered by horse and cart.

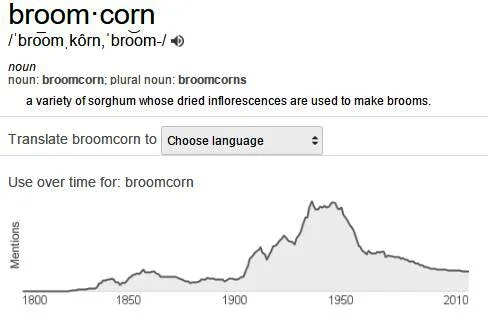

So what is broomcorn? By Google's definition you find..

But that doesn't really cover the all the intricate detail that a broomcorn dealer must know. What does the plant look like? Where is best broomcorn grown? What type of broomcorn makes the world's best and beautiful broom?

Let's dig a little deeper.

If you drove by a broomcorn field, you might think it was just an acre of sweet corn stalks. The sweet corn stalks like broomcorn are both part of the sorghum genus which is part of the grass family.

The broomcorn seeds grow beyond the stalk of the 6-9' plant into lengthy sturdy fibers which are harvested by hand. Due to the labor extensive process, most broomcorn is now harvested in Mexico where the dry and hot climate is also ideal.

Broomcorn field.

Broomcorn is harvested as either 'raw' corn or 'processed hurl'. Raw broomcorn has been cleaned but left with 'flowers' in the wavy tip and the stalk is completely attached. Processed hurl has the stalk completely removed and cleaned entirely.

Processed broomcorn hurl's clean and wavy tip.

For further reading on broomcorn, please visit here. http://www.hort.purdue.edu/newcrop/afcm/broomcorn.html

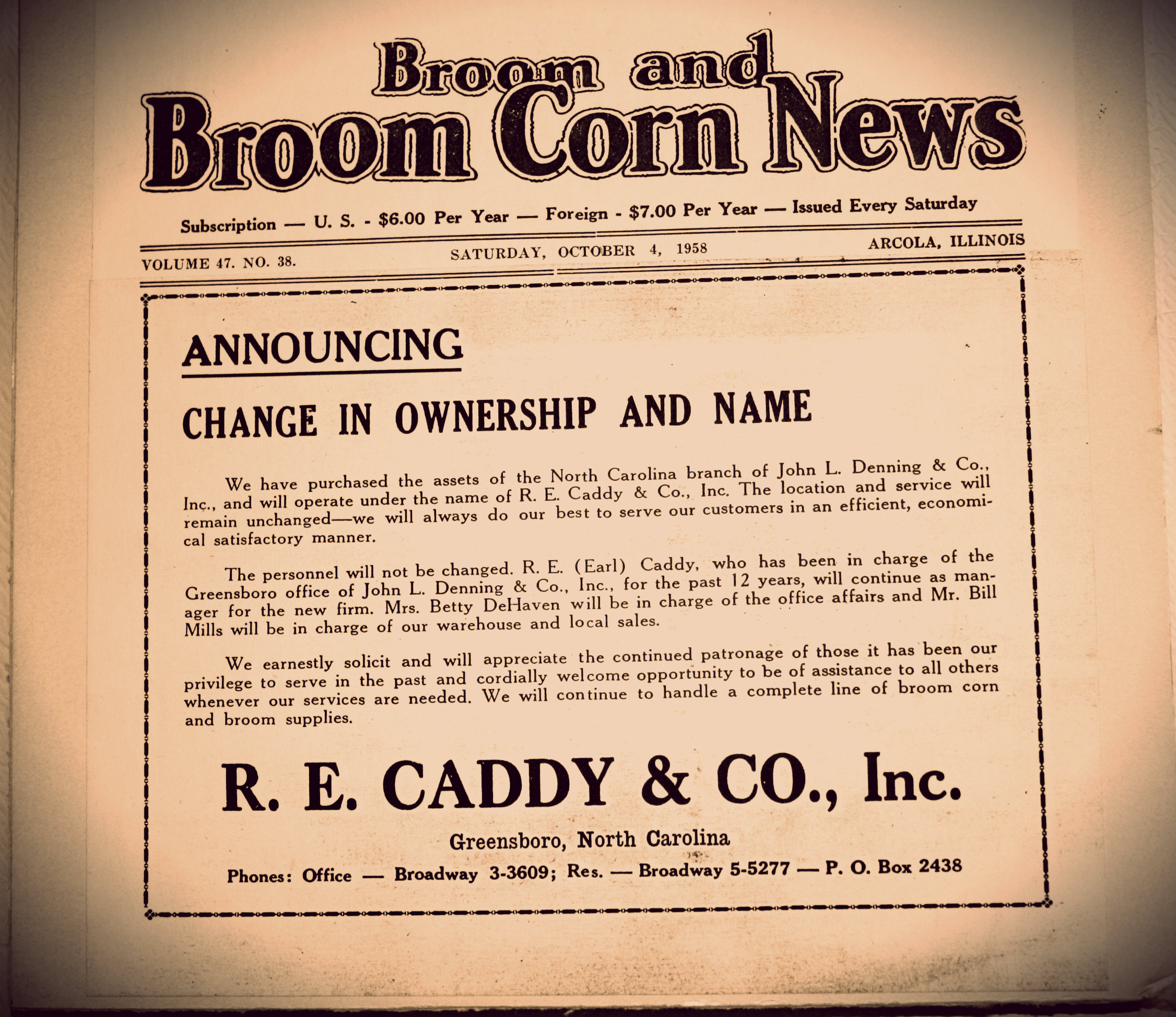

As of spring 2016, Caddy Supply Company is the new name of R.E. Caddy & Company Inc.

R.E. Caddy & Company Inc was originally founded in 1958 by Richard Earl "Tip" Caddy Sr. For over 50 years, The business has supplied craft and processed broom corn, palmyra and yucca fiber; wood broom, brush and mop handles; wet mop hardware and handles; polyethylene broom sewing twine; nails, knives and other supplies.

Richard Earl "Tip" Caddy Senior was born in Cincinnati, Ohio in 1916 and passed in 2004. He was a member of Holy Trinity Episcopal Church, where he was a vestryman and junior and senior warden. Mr. Caddy graduated from the University of Cincinnati. Mr. Caddy served in WW II in the Army Air Corps. He was former board man and president of American Brush and Broom Manufacturers.

Richard Caddy has an impressive 33 years in broomcorn business. He joined RE Caddy & Co, Inc as Vice President in 1983 and became President in 1985. He created the special craft broom maker program in 1994 and launched an online store in 2003. He has a BA from UNC, 1971 and MPA from UNC, 1974.

When it comes to customer service, Caddy explained, R.E. Caddy has emphasized communicating with customers to remain current on their operations and their needs.

“We establish relationships with customers to know what kind of materials they require, and to anticipate when they are going to need to order,”

Some people like to work plans with us in terms of blanket purchase orders. For others, we have ready inventory where we can ship fairly close to any date that an order is given — if not same day. We pay attention to our quality because that is important no matter what the application. We just try to treat our customers the best we can.”